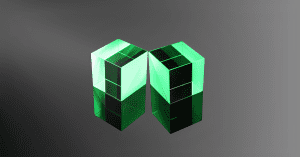

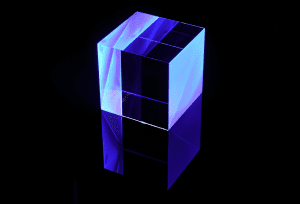

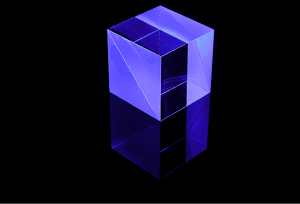

Laser Line Polarizing Plate Beamsplitters

Our laser line polarizing plate beamsplitters are engineered to handle randomly polarized light, separating it into distinct polarized components at a 45° angle of incidence. With a high damage threshold, these beamsplitters are ideal for high energy YAG laser applications. Available in 12.5mm, 25mm, and 50mm square sizes, they feature advanced thin-film coatings for superior performance. Constructed from UV-grade fused silica, they offer excellent thermal stability and low wavefront distortion. Uncoated versions are also available in 12.5mm and 25mm sizes, with a 5-arc-second wedged option upon request for enhanced precision.

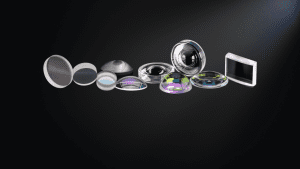

At Avantier, we specialize in crafting custom laser line polarizing plate beamsplitters, supporting everything from prototyping to large-scale production. Whether you’re working with lasers, microscopy, or imaging systems, our expertise in light manipulation ensures tailored solutions for your unique optical needs. Avantier is your trusted partner in developing cutting-edge polarizing beamsplitter cubes and other customized optical components.

- Ratio and Polarization Insensitivity: These beamsplitters are optimized to split linearly polarized light into S- and P-polarized components, with a balanced 50% reflectance (R) and 50% transmittance (T) ratio. They are an excellent choice for applications that do not require maintaining the input beam’s polarization.

- Multiple Sizes: Available in 12.5mm and 25mm diameters, as well as a 50mm square variant, these beamsplitters are adaptable for a variety of optical setups requiring control over polarized light.

- High Power Endurance: Designed to withstand high-powered laser beams, particularly YAG lasers, these polarizing beamsplitters offer a robust damage threshold, making them suitable for high-intensity laser environments.

- Thin-Film Coating for Enhanced Performance: The advanced anti-reflective (AR) thin film V-coating minimizes reflective losses and maximizes the efficiency of light transmission and reflection, delivering top-tier performance in laser applications.

- Superior Substrate: The beamsplitters are crafted from excimer-grade UV-grade fused silica, renowned for its high optical clarity, low auto-fluorescence, and superior thermal stability. With a surface quality of 10-5 and 3 arc second parallelism, they provide exceptional precision and performance.

- Uncoated Options Available: For more customization, uncoated substrates are available in 12.5mm and 25mm sizes, offering flexibility for specialized coatings or applications that benefit from an uncoated surface.

Factory Standard

Material | Grade Fused Silica, JGS1, JGS2 |

Dimensions | +0.00 / -0.10mm |

Surface Quality | 40-20 |

Surface Flatness (P-V) | λ/4 |

Clear Aperture (%) | 90 |

Beam Deviation (arc sec) | ±3 |

Custom Laser Line Polarizing Plate Beamsplitters

These versatile laser line polarizing plate beamsplitters are indispensable optical elements for laser applications. Our products’ attributes–such as the 50R/50T ratio, polarization insensitivity, size options, durability against intense laser power, premium coatings, and superior substrate quality–position them perfectly for integration into a variety of laser systems and configurations, delivering precision and reliable performance. The use of high-quality r substrate materials further bolsters their stability and durability.

If you have questions about laser line polarizing plate beamsplitters, don’t hesitate to contact us. Our experienced optical designers are always available to discuss your custom project.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.