Highlights

- Advanced precision custom optical design and engineering, coupled with expert optical lens assembly, define Avantier’s core competencies in the field of optical manufacturing.

- We pride ourselves on holding certifications including ISO 9001:2015, ISO 13485:2016, and ISO 14001:2015, ensuring the highest standards of quality and environmental management.

- Backed by our experienced QA team, who undergo regular audits to maintain ISO compliance, we are dedicated to meeting your specific requirements with unwavering precision. Our commitment to excellence guarantees guaranteed lead times and competitive F.O.B. shipping terms from our New Jersey facility, ensuring optimal delivery and cost savings for our domestic customers.

Custom Optical Projects & Manufacturing

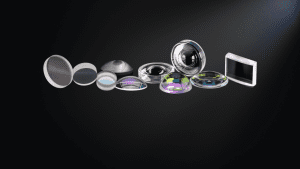

Avantier offers advanced precision custom optical design, optical engineering, optical lens assembly, rapid optical proto-typing, image processing, and manufacturing services. Our expertise lies in crafting optical and optomechanical systems, ranging from individual components to comprehensive assemblies, covering a spectrum from direct view to imaging and laser optics, extending from the UV to IR wavelengths. Our design engineers possess adept skills in tolerancing and intricate optical and mechanical analysis. Therefore, Avantier’s engineers stand ready to guide your project seamlessly from initial design through prototyping to full-scale production.

Custom Optical Projects

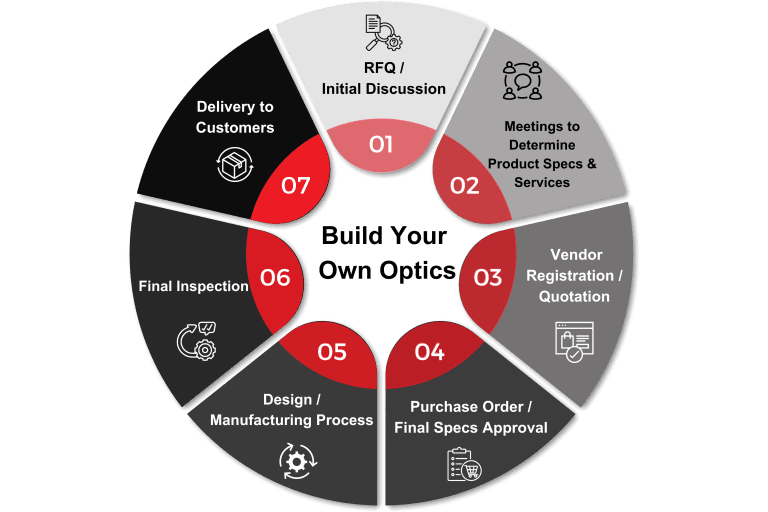

- Custom Component & Optical Lens Assembly Projects Process:

- RFQ/Initial Discussion

- Meetings to Determine Product Specs & Services

- Vendor Registration / Quotation

- Purchase Order / Final Specs Approval

- Design / Manufacturing Process

- Final Inspection

- Delivery to Customers

- Optical Design and Layout, Mechanical Design, Element Analysis, Optical Film Design, Rapid Prototyping.

- Our designers use Zemax, AutoCAD, and CODE V Design software to optimize design and manufacturability.

- Reverse Optical Engineering

- Reverse optical engineering entails creating plans and specifications for a lens or optical assembly based on an existing sample or prototype to replicate or enhance the original design.

- It involves meticulous disassembly, testing, and mapping of components.

- Redesigning occurs based on precise specifications derived from the analysis.

Manufacturing Capability

- Facility

- United States of America

- Certificates

- ISO: 9001:2015

- ISO: 13485:2016

- ISO: 14001:2015

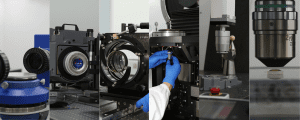

Avantier’s lens manufacturing process ensures superior quality with precise shapes and smooth finishes. For instance, lens grinding and polishing involves meticulous manual and automated steps, maintaining defined tolerances for exceptional accuracy.

- Lens Milling and Grinding

- Lens Grinding and Polishing

- MRF Polishing with Q-flex 300 MRF™ Polishing Machine

- Precision Optics Polishing with Satisloh SPS-200

- Precision Lens Cutting with Sidai SPCM-M1

- Immersive Ultrasonic Cleaning Process

- Nanotech 250 UPL for Precision Diamond Turning

- KERN EVO CNC Machining Center

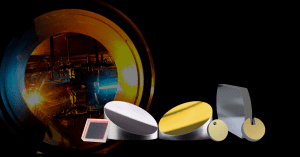

- Optical Coatings

- Specializes in the process that involves applying thin films to optical components, enhancing light transmission, modifying reflection, or manipulating polarization.

- Various types of coating: including filter, beam splitter, high-reflective, low-reflective, and anti-reflection coatings, each serving distinct purposes.

- Offers cutting-edge technologies like IAD E-Beam, IBS, PARMS, and APS.

- Metrology

- At Avantier, we design optical solutions systems and produce high performance optics for optical metrology equipment for various applications.

Zygo Verifire DynaFiz Interferometer |

Zygo 18-inch Aperture Mark IV |

TriOptics MTF Stations |

LUPHOScan 420 |

TriOptics OptiCentric 100 Dual |

Zygo 3D Optical Surface Profiler-NewView™ 9000 |

Agilent Cary 7000 Spectrophotometer |

Leitz PMM Gold |

Panasonic UA3P-300 3D Profilometer |

- Quality Assurance

- Our QA team undergoes regular audits to comply with ISO standards. All products undergo thorough cleaning and 100% visual inspection by an experienced QA team before shipment. We adhere strictly to surface quality specifications.

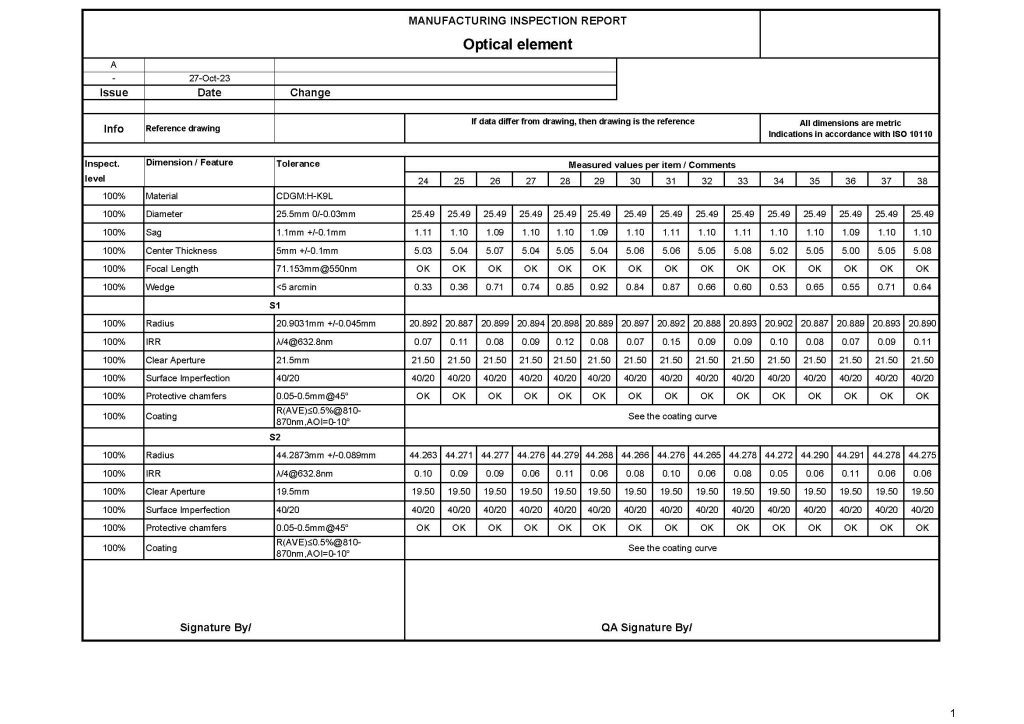

- Inspection Report: An inspection report is a document generated by Avantier, detailing the results of quality control checks conducted on optics produced during manufacturing. This report serves as a formal record of the inspection process and provides essential information regarding the optical components’ quality, functionality, and compliance with specifications and standards.

- Warranty Policy

- Delivery

- Careful packing ensures parts arrive in optimal condition.

- Every part leaving our inspection room is impeccably clean and meets standards.

- We deliver within our guaranteed lead time. every order will have its delivery date after we confirm the PO.

- All prices are F.O.B. New Jersey. Our shipping terms, set at FOB, NJ, offer a competitive and convenient advantage.

Unlock the pinnacle of precision with Avantier’s custom and high-end optical solutions. From design to manufacturing, we specialize in crafting catered optical projects with unmatched expertise. Whether you’re delving into optical design, assembly, or reverse engineering, our team stands ready to bring your vision to life. With cutting-edge technology, state-of-the-art facilities, and rigorous quality assurance, trust Avantier to seamlessly guide your project to success. Contact us and experience optical excellence like never before.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.