Avantier’s Lens Manufacturing Process

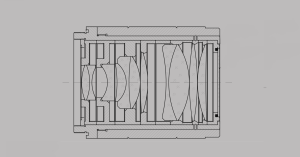

At Avantier, precision optics is more than a specialty—it’s our foundation. With decades of experience and cutting-edge technology, we deliver custom optical components to industries such as Aerospace & Defense, Life Sciences, Medical Imaging, and Semiconductors. Our lens manufacturing process is designed to meet the most demanding requirements, combining tight tolerances, optical clarity, and durability.

1. Lens Milling and Grinding

The journey begins with precision shaping of raw optical blanks. Our advanced milling and fine grinding technologies achieve tight dimensional control and surface quality, creating the foundation for high-performance lenses. Automated processes ensure uniformity and defect reduction across production batches.2. Lens Polishing and Grinding

Our multi-step polishing process starts with manual abrasive grinding and transitions into high-speed fine grinding. We use both traditional pitch polishing and CAD/CAM-controlled polishing techniques to remove micro-defects and achieve high surface accuracy. Every lens undergoes thickness monitoring and quality checks at each stage using precision metrology tools such as interferometers and micrometers.3. MRF Polishing with Q-flex 300

Magnetorheological Finishing (MRF) provides targeted correction of surface form errors. Avantier uses the Q-Flex 300 MRF™ system to polish complex shapes—including spheres, aspheres, and freeforms—with nanometer-level precision. MRF is ideal for optics that demand localized surface correction and extreme accuracy.4. Precision Optics Polishing with Satisloh SPS-200

For high-volume and complex optics, our Satisloh SPS-200 system delivers precision polishing of spheres, aspheres, cylinders, toroids, and freeform surfaces ranging from 5 to 200 mm. Advanced features like Synchrospeed, Variospeed, and ADAPT technology enable custom surface shaping with repeatable accuracy.5. Precision Diamond Turning (Optional for IR and Metal Optics)

Avantier’s Nanotech 250 UPL diamond turning lathe is used for producing infrared optics or metal mirrors with ultra-smooth surfaces and complex geometries. This process often eliminates the need for post-polishing, especially for non-glass optical materials.6. CNC Machining of Mechanical Features

Our KERN EVO CNC machining center ensures accurate shaping of non-optical surfaces such as mounting edges, housings, and filter frames. With spindle speeds up to 50,000 RPM, it supports fast, high-precision machining with exceptional surface finish.7. Precision Lens Cutting with Sidai SPCM-M1

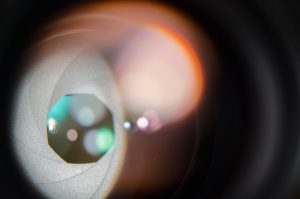

Once optical surfaces are polished, lenses are cut to final size using the Sidai SPCM-M1. This system ensures flawless edge geometry and consistent centering, with robot-assisted loading and unloading for high-throughput efficiency.8. Immersive Ultrasonic Cleaning Process

Optics are thoroughly cleaned using solvent immersion and ultrasonic agitation to remove contaminants from polishing and machining. This step ensures every surface is pristine prior to coating or metrology.9. Optical Coating

Avantier offers a full range of thin-film coatings, including AR, beamsplitter, high-reflective, low-reflective, and filter coatings. Technologies such as IAD E-beam, IBS, APS, and PARMS allow us to tailor coating performance to specific wavelengths, polarization, and durability requirements.10. Sub-Aperture Stitching Interferometry (SSI)

At the final stage, Sub-Aperture Stitching Interferometry is used for high-precision surface metrology. SSI combines multiple overlapping scans to reconstruct full-aperture surface data of large or complex optics. This technology is essential for verifying form accuracy in aspheric, freeform, and large-aperture components, guiding final corrective polishing where needed.Partner with Avantier

Avantier provides end-to-end optical manufacturing solutions—from design and prototyping to volume production. Whether you’re building advanced imaging systems, medical diagnostic devices, or next-gen aerospace optics, we’re here to support your innovation with world-class quality and precision.

Contact us today to begin your next optical journey.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.