Optical Metrology Overview

Optical metrology, the science of using light for measurement, covers a range of applications. It involves measuring properties of light itself or using light to gauge characteristics like temperature, dimensions, or distance of objects. At Avantier Inc., we utilize cutting-edge optical metrology equipment to manufacture and test precision optical components and systems. Each part undergoes thorough inspection, adhering to customer-specific requirements and MIL/SPEC. Comprehensive inspection reports, material certificates, and coating curves (if applicable) accompany all shipments. Our state-of-the-art in-house metrology equipment ensures compliance with international measurement standards throughout the optical production process. We prioritize meeting customer needs, from raw material procurement to final production, following ISO: 9001 standards for strict control and monitoring of all orders.

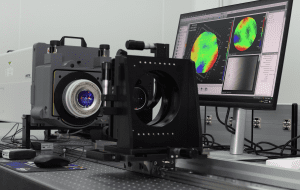

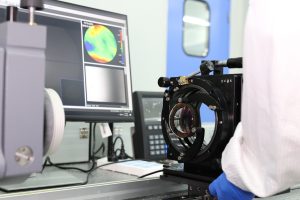

Interferometer

The Zygo Verifire Interferometer is a cutting-edge metrology instrument with diverse applications and significant advantages. This sophisticated interferometer system is widely used in the optics industry for high-precision measurement and analysis of optical components and systems. Its primary application includes the characterization of surface form error, transmitted wavefront, and surface flatness of optical elements such as lenses, mirrors, prisms, and windows. The instrument’s capabilities are not limited to optical components alone; it can also be employed for precision machined metal and ceramic surfaces.

One of the key advantages of the Zygo Verifire Interferometer lies in its ability to deliver fast and reliable measurements in a variety of environments, even in the presence of vibration and air turbulence. The incorporation of the QPSI (Quad Pass Shear Interferometry) technology ensures robust data acquisition, enabling reliable measurements in challenging conditions on the shop floor or in research laboratories.

Another major advantage is its true laser Fizeau design, which utilizes a ZYGO-made HeNe laser source. This laser source boasts a longer lifetime compared to commercially available lasers, providing 60,000 hours of operation, backed by a remarkable 3-year warranty. With its higher power and wavelength stability of 0.0001 nm, the laser ensures enhanced vibration performance and accuracy in low-light applications, setting the Verifire apart from conventional interferometers.

Moreover, the system’s full-featured Mx™ software facilitates powerful yet user-friendly measurement, analysis, and automation capabilities, streamlining the data processing and interpretation workflow for users. Overall, the Zygo Verifire Interferometer stands as an indispensable tool in the optics industry, empowering manufacturers and researchers to achieve exceptional precision and quality control in their optical components and systems, elevating the standard of modern optical metrology.

Interferometers play a crucial role in optical metrology, which is the science and technology of measuring and characterizing optical properties and phenomena. Interferometry is a powerful technique that exploits the wave nature of light to make highly accurate measurements of various parameters. Their ability to exploit the wave nature of light enables them to be applied in a wide range of applications, from industrial manufacturing and quality control to scientific research and medical diagnostics. For more information, or to discuss manufacturing limits and your custom metrology request for a quote on your next project, please contact us.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.