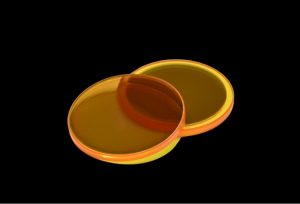

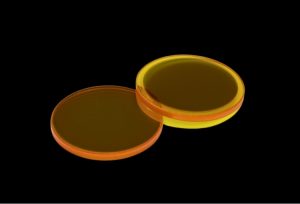

ZnSe Optical Windows

A ZnSe window, composed of Zinc Selenide, is an optical window known for its transparency and high stability. It exhibits minimal infrared (IR) absorption and can withstand thermal shock effectively. The transmission range of these windows spans from 0.5 μm to 22 μm.

ZnSe optical windows find common applications in Forward Looking Infrared (FLIR) and thermal imaging systems. Additionally, they serve as resonator windows in high-power CO2 laser systems operating at 10.6 microns. Zinc Selenide, characterized by low dispersion, a low absorption coefficient, a density of 5.27 g/cm3, and a refractive index near 2.4, does not absorb moisture from the air, making it non-hygroscopic.

The ZnSe utilized in our windows undergoes Chemical Vapor Deposition (CVD) to achieve extreme purity, reaching 99.999%. In this process, zinc vapor and H2Se gas react to form ZnSe sheets on graphite susceptors, which are then precisely shaped into optical windows.

Due to ZnSe’s softness (Knoop number of 105), these optical components require careful handling and are not suitable for harsh environments. However, their softness imparts resilience to thermal shock, allowing them to endure thermally demanding conditions. This property, along with their chemical stability, makes ZnSe windows crucial in various applications, including medical, industrial, and defense imaging.

When handling ZnSe windows, it is crucial to grasp them only by their edges, applying uniform pressure to prevent warping. Cleaning should be done with great care to avoid scratching the soft surface. Dust can be removed with a dust-free blower or air bulb, and if further cleaning is necessary, acetone or isopropyl alcohol can be used. Cleaning should involve gentle wiping with a damp cotton ball, without rubbing or exerting pressure, using surgical-quality cotton balls.

Because Zinc Selenide is toxic, protective rubber gloves are essential when handling windows or lenses made from this material.

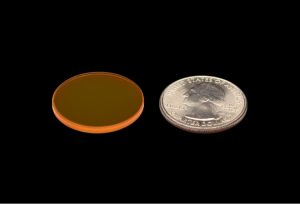

Avantier maintains high-quality standards in its factory, with careful inspections to ensure that Zinc Selenide optics meet specified criteria. Factory standards include a clear aperture of over 85% and a wavefront distortion of no more than l/4 per 25mm. Avantier offers ZnSe windows in various sizes and thicknesses, with diameter tolerance set at no more than +0.0, -0.05mm, and thickness tolerance at no more than +/- 0.1mm. Both AR coated and noncoated options are available.

ZnSe windows

Factory Standard

Material | ZnSe |

Irregularity (fringe) | l/4 |

Diameter Tolerance | +0.0, -0.05mm |

Thickness Tolerance | +/- 0.1mm |

Clear Aperture | >85% |

Parallelism | 5 arc min |

Surface Quality | 40-20 |

Wavefront Distortion | l/4 per 25mm |

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.