Polarizing Beamsplitters

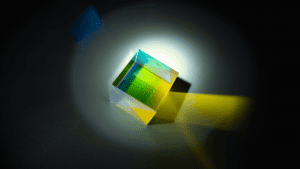

A polarizing beamsplitter is an optical component designed to split light into two directions, dividing it by polarization state. Beamsplitters consist of high-quality optical glass, and most polarizing beamsplitters are designed to split light into reflected s-polarized and transmitted p-polarized beams. For incident light entering at a 0° or 45° angle, the beamsplitter separates the two polarized beams at a 90° angle. When two displaced parallel beams are required, a lateral displacement beamsplitter can be used. Avantier offers cubic, plate, and lateral displacement beamsplitters with tight tolerance on all parameters, making us a premium source for all your custom beamsplitter needs. Our experienced optical engineers and designers can help you determine the perfect beamsplitter for your requirements.

Types of Polarizing Beamsplitters

Polarizing beamsplitter can be divided into three categories: polarizing plate beamsplitters, cube beamsplitters, and lateral displacement beamsplitters. All three types separate the light radiation into two beams with orthogonal polarization. In a perfect beamsplitter, the ratio of reflected to transmitted light will always be 50/50.

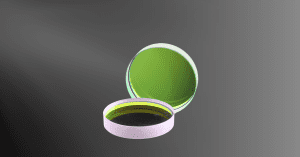

- Polarizing plate beamsplitters are typically designed with special hard coatings on the front surface of an optical substrate, such as UV fused silica. With a high damage threshold, they are ideal when high transmission, a high extinction ratio, and a high damage threshold are necessary. A polarizing plate beamsplitter has distinct front and back sides and is designed to be used at a 45° angle of incidence. Typically, a small arrow is engraved on the beamsplitter to indicate the appropriate direction of light. S-polarized light will be reflected at 45°, while p-polarized light will be transmitted.

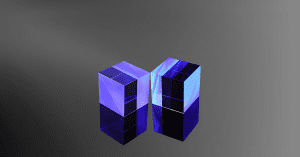

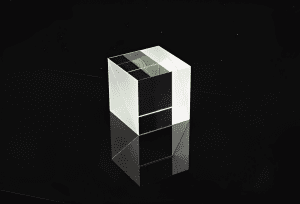

- Polarizing cube beamsplitters are formed from two prisms, one of which has a dielectric beam-splitting coating on the hypotenuse side. The two prisms are placed with their hypotenuse sides against each other and bound with optical cement. Light may enter any of the polished square faces of the cube, which will split light into s- and p-polarized beams. These beamsplitters are a great choice when durability or simplified mounting and system integration is required. They are typically manufactured with a broadband anti-reflection coating on all faces. For laser line cube beamsplitters, our clients can choose AR coatings optimized for 532 nm, 633 nm, 780 nm, 980 nm, 1064 nm, or 1550 nm laser wavelengths.

- A lateral displacement beamsplitter is formed by a rhomboid prism cemented to a λ/8 right-angle prism. Both the entrance and exit faces are typically coated with high-quality anti-reflection coatings, as well as polarizing coatings. Although less common than cube or plate beamsplitters, lateral displacement beamsplitters are highly desirable for simplifying benchtop layouts.

Applications of Polarizing Beamsplitters

Polarizing beamsplitters are crucial in systems requiring the separation of s- and p-polarized light. For instance, in semiconductor and photonics instrumentation, a beamsplitter transmits p-polarized light and reflects s-polarization light. Polarizing beamsplitters are also used in optical isolators to prevent feedback-induced damage, as the transmitted beam consists entirely of polarized light.

Factory Standard

Material | Schott, Ohara, CDGM Optical Glass, Corning fused silica, JGS1, JGS2 |

Surface Flatness | λ/4 |

Dimensions | +0.1 mm |

Beam Deviation | < 5 arcmin |

Surface Quality | 40-20 |

Extinction Ratio | 100:1 |

Custom Polarizing Beamsplitters

At Avantier, we design and manufacture plate beamsplitters (in both round and rectangular configurations), cube polarizing beamsplitters, and lateral displacement beamsplitters. A variety of substrates and coating options allow us to customize your polarizing beam splitter order to meet desired wavelength ranges and power-handling requirements.

Our beamsplitters have an extinction ratio of 100:1, along with high surface quality and surface flatness. We also produce Brewster windows and birefringent crystals that are highly resistant to laser damage, providing polarization cleanup in potentially compromising situations.

Please contact us for more information on our manufacturing capabilities or to schedule an introductory consultation.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.