MEMS Mirrors for High-Speed Beam Steering and Precision Scanning

Avantier’s MEMS mirrors (Micro-Electro-Mechanical Systems mirrors) deliver compact, high-speed, and energy-efficient beam steering performance for advanced optical systems. Designed with precision semiconductor processing, our MEMS scanning mirrors provide reliable, high-accuracy optical control for next-generation photonics applications.

What Are MEMS Mirrors?

MEMS mirrors are micro-fabricated reflective structures capable of tilting or rotating at high speeds using electrostatic, electromagnetic, or piezoelectric actuation. Their small size, fast response, and low power consumption make them ideal for compact scanning and projection systems.

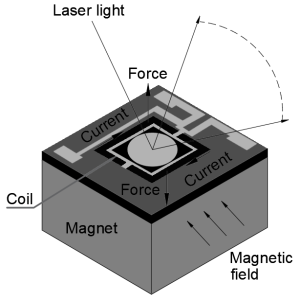

How MEMS Mirrors Work

A MEMS mirror consists of:- Mirror Surface — Silicon or metal-coated reflective element

- Actuators — Electrostatic (standard), electromagnetic, or piezoelectric

- Torsion Springs — Provide controlled angular deflection

- Support Substrate — Houses mechanical structure and interface circuitry

- Scan ranges: ±5° to ±25°

- Resonant frequencies: Up to 30 kHz

- Low power operation

Single-axis or dual-axis scanning

Key Applications of MEMS Mirrors

LiDAR & 3D Sensing

- Real-time 3D environment mapping

- Automotive, robotics, industrial automation

Optical Communication

- Signal switching

- Beam alignment

- Dynamic routing

AR/VR Display Technology

- Near-eye displays

- Light-steering projection

- Miniaturized wearable optics

Biomedical Imaging

- OCT scanning

- High-speed microscopy

- Laser diagnostics

Laser Projection & Scanning

- Mobile projection systems

- Industrial marking

- Pattern generation and inspection

MEMS Mirrors vs. Galvo & Solid-State Scanners

A comparison designed to help engineers choose the right solution.

Feature |

MEMS Mirrors |

Galvo Mirrors |

Solid-State Scanners |

Speed |

Very high (up to 30 kHz) |

Moderate |

Low–moderate |

Size |

Ultra-compact |

Larger |

Compact |

Power Use |

Very low |

High |

Low |

Scan Angle |

Moderate |

Large |

Limited |

Ideal For |

LiDAR, AR/VR, OCT, micro-scanning |

Laser marking, engraving |

Depth sensing, lidar-lite |

Custom MEMS Mirror Solutions from Avantier

We provide fully customizable MEMS mirror designs, including:

- Mirror Aperture: 1–5 mm or fully custom shapes

- Actuation Options: Electrostatic, electromagnetic, piezoelectric

- Coatings: UV, visible, NIR, IR optimized

- Scan Angle Tuning: Custom ranges & frequencies

- Environmental Options: Vacuum-compatible, hermetically sealed

- Integrated Electronics: Drive/control circuitry included

- Optical System Consulting: Full design and integration support

Avantier works closely with your engineering team to create MEMS beam-steering solutions that match exact system requirements.

Get a High-Performance MEMS Mirror Tailored to Your System

We provide rapid prototyping, custom design, and volume production.

📩 Contact us: https://avantierinc.com/contact/

📋 Online Inquiry Form: https://avantierinc.com/request-for-quote/

Frequently Asked Questions

Q1: What is a MEMS mirror?

A MEMS mirror is a micro-fabricated reflective device that deflects light via electrically driven motion. It enables high-speed scanning in compact optical systems.

Q2: Which industries use MEMS mirrors?

LiDAR, AR/VR displays, biomedical imaging (OCT), optical communication, robotics, and projection systems.

Q3: What scan angles and frequencies are typical?

Scan ranges from ±5° to ±25°, and resonant frequencies up to 30 kHz depending on aperture size and actuation method.

Q4: Are MEMS mirrors suitable for LiDAR?

Yes. MEMS mirrors enable high-speed scanning for automotive and robotics LiDAR systems while keeping size and power consumption low.

Q5: Does Avantier offer custom MEMS mirrors?

Yes. Avantier provides custom apertures, coatings, actuation mechanisms, environmental packaging, and electronics integration.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.