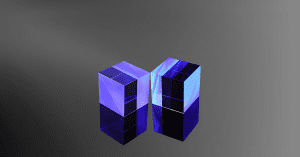

Laser Line Non-Polarizing Plate Beamsplitters

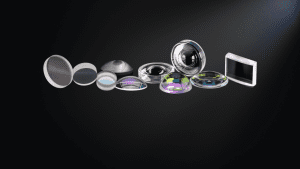

Avantier specializes in designing and manufacturing custom laser line non-polarizing plate beamsplitters, from prototyping to large-scale production. Our expertise enables applications in microscopy, lasers, and imaging, where precise light manipulation is crucial. We prioritize minimizing wavefront distortion to ensure optimal beam quality and performance in your optical systems. Discover Avantier as your trusted partner for tailored optical solutions at any production stage.

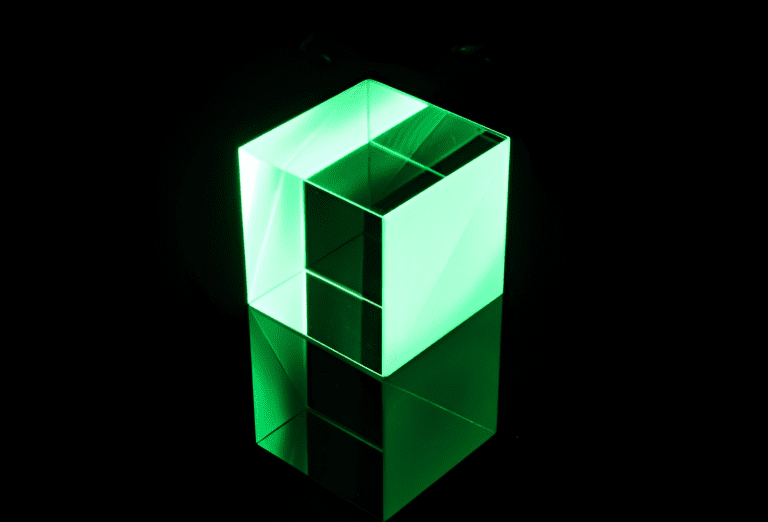

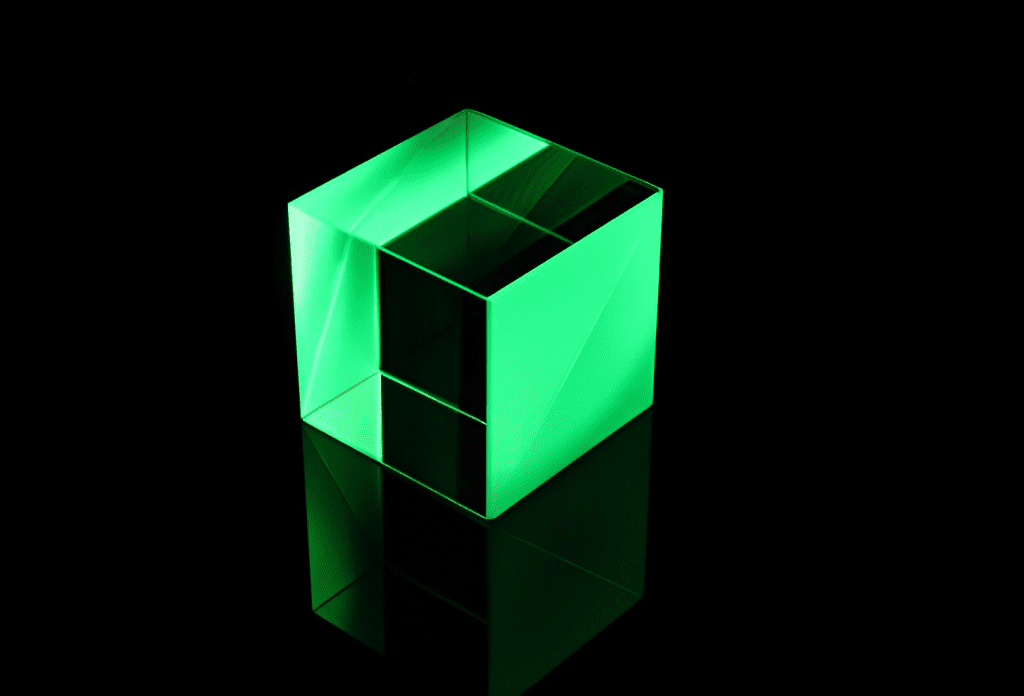

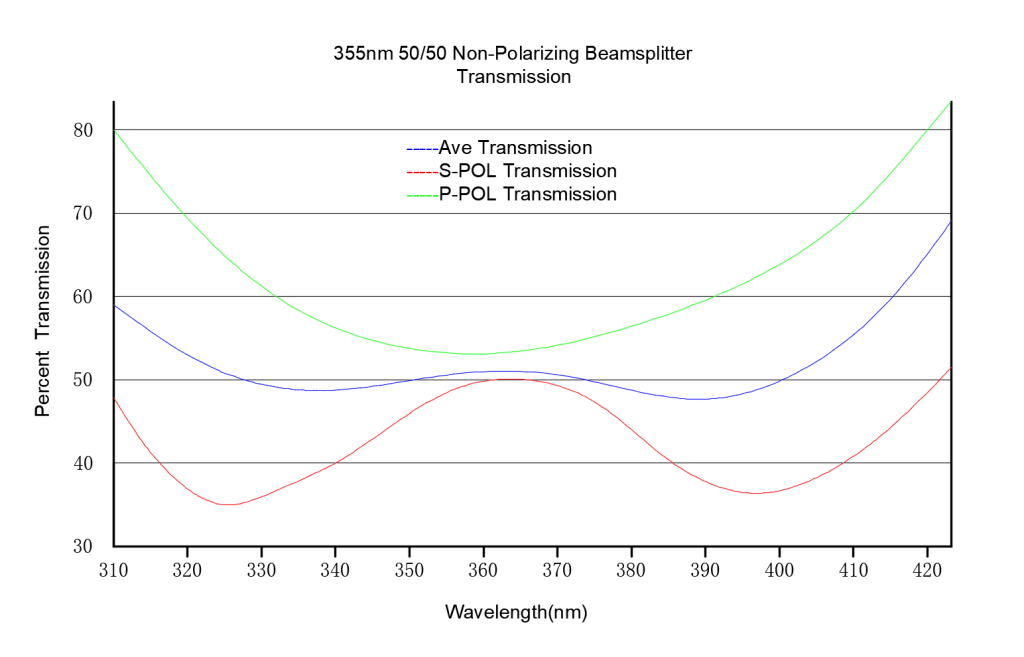

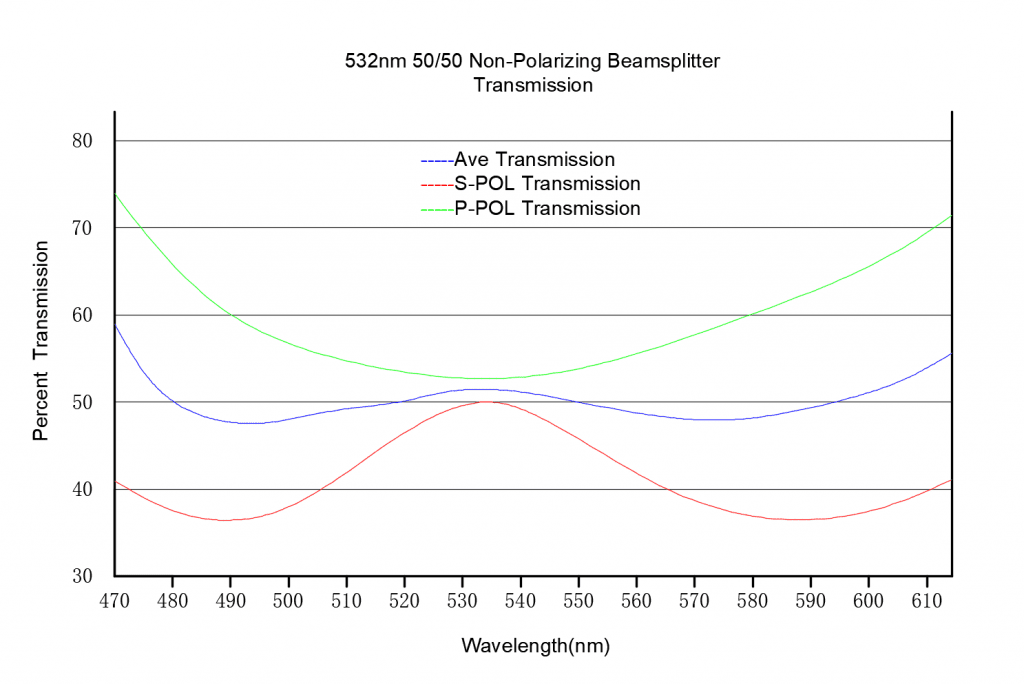

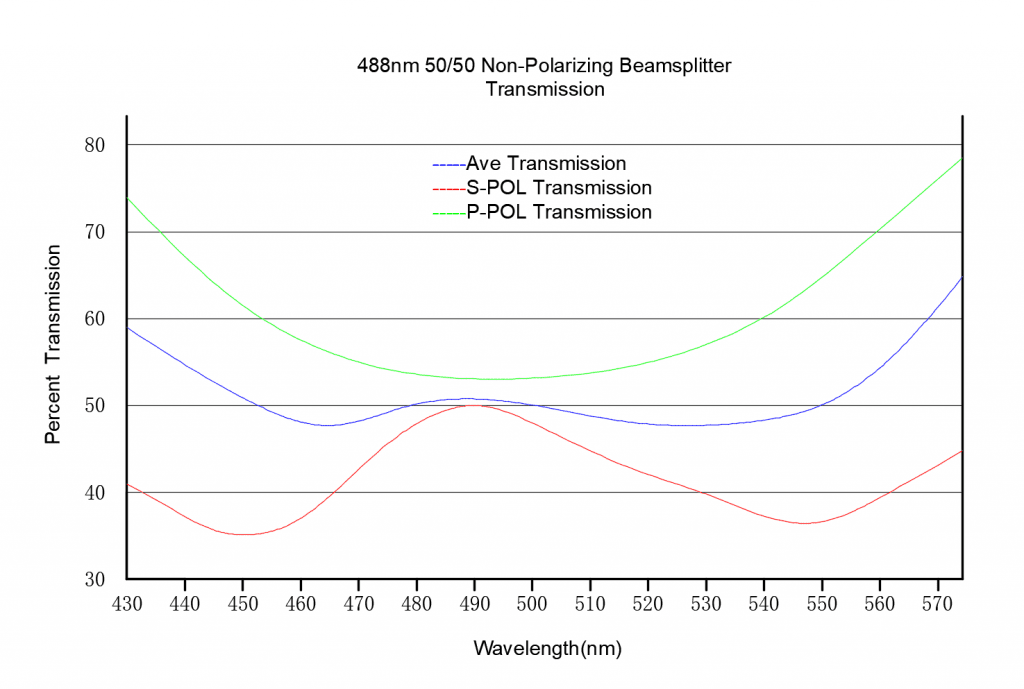

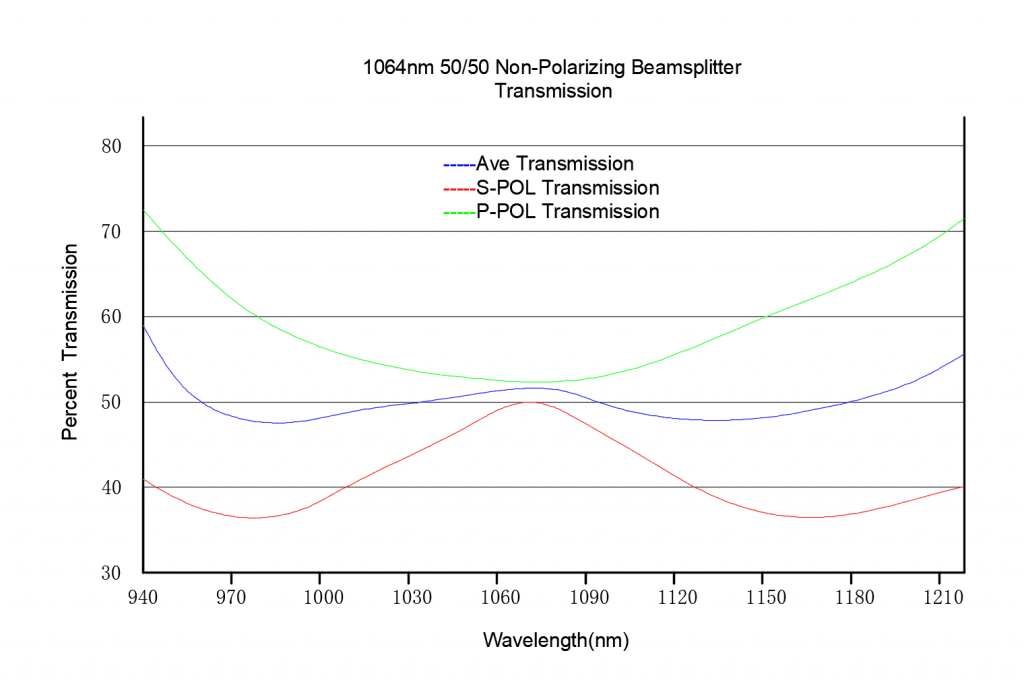

- Ratio and Insensitivity to Input Beam Polarization: The laser line non-polarizing plate beamsplitters have a 50% reflectance (R) and 50% transmittance (T) ratio, meaning they split the incident laser beam into two equal-intensity beams. Additionally, these beamsplitters are designed to be insensitive to the polarization of the input beam, Making them when maintaining the polarization state of the laser light is not critical for the application.

- Sizes: The beamsplitters are available in three sizes: 12.5mm and 25mm diameters, and a 50mm square option. This range of sizes allows flexibility in integrating the beamsplitters into various optical setups.

- High Damage Thresholds: The laser line non-polarizing plate beamsplitters are designed to withstand high-power laser beams without sustaining damage, a crucial feature for laser applications where light intensity can be quite high.

- AR V-Coating: The beamsplitters feature a high-efficiency anti-reflective (AR) V-coating, which helps minimize reflection losses at the surfaces, enhancing overall performance.

- Fused Silica Substrate: The substrate, the base material of the beamsplitter, is made of precision excimer-grade UV-grade fused silica, known for its excellent optical properties, including low auto-fluorescence (minimizing unwanted light emission) and thermal stability. The substrate boasts a surface quality of 10-5 (very smooth) and a parallelism of 5 arc seconds (high precision alignment of surfaces).

- Uncoated Substrates: In addition to coated beamsplitters, uncoated substrate options are available in both 12.5 mm and 25 mm sizes, providing flexibility for custom coatings or specific applications where a coating is not desired.

Factory Standard

Material |

UV Grade Fused Silica, JGS1, JGS2 |

Dimensions |

+0.00 / -0.10mm |

Surface Quality |

10-5 |

Clear Aperture |

80% |

Parallelism |

5 arc sec |

Custom Laser Line Non-Polarizing Plate Beamsplitters

The laser line non-polarizing plate beamsplitters described are versatile optical components designed for laser applications. Their features—such as the 50R/50T ratio, insensitivity to input beam polarization, range of sizes, high damage thresholds, and quality coatings—make them ideal for integration into various laser systems and setups that require precision and reliability. The use of high-quality substrate materials further enhances their performance and stability.

If you have more questions about laser line non-polarizing plate beamsplitters, don’t hesitate to contact us. Our experienced optical designers are always available to discuss custom orders.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.