Large Optics Solutions by Avantier

Precision-Engineered Large Diameter Optics for Advanced Imaging and Photonics

Avantier specializes in large scale optics—precision optical components with diameters exceeding 100mm—engineered for high precision performance in even the most demanding environments. Our solutions are designed to elevate applications in astronomy, aerospace, satellite communication, laser systems, and scientific imaging where high power and accuracy are critical.

What Are Large Optics?

Large optics refer to optical elements like lenses, mirrors, prisms, domes, and windows that surpass 100 mm in diameter. These components:

- Enable high-resolution imaging with minimal aberration

- Support large apertures for superior light-gathering capability

- Maintain performance across extreme temperatures, vibrations, and environments

Why Choose Avantier for Large Optics?

- Custom Fabrication: Tailored to meet complex and unique design parameters

- Advanced Coatings: High-durability coatings including AR, HR, dielectric, and custom wavelength-specific options

- Precision Manufacturing: Tight tolerances, interferometric testing, and high laser-induced damage threshold (LIDT) verification

- Wide Material Selection: BK7, fused silica, ZnSe, ZnS, Germanium, Chalcogenide, Sapphire, Silicon, and more

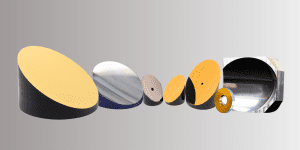

Product Portfolio

- High image quality with minimized aberrations

- Low-light enhancement through larger apertures

- Coatings for UV, visible, IR, and broadband applications

Ideal for beam steering and imaging systems such as:

- Telescopes, remote sensing instruments, and LIDAR

- Precision-manufactured reflective surfaces with optional metal or dielectric coatings

- Available in flat, spherical, or off-axis parabolic (OAP) formats

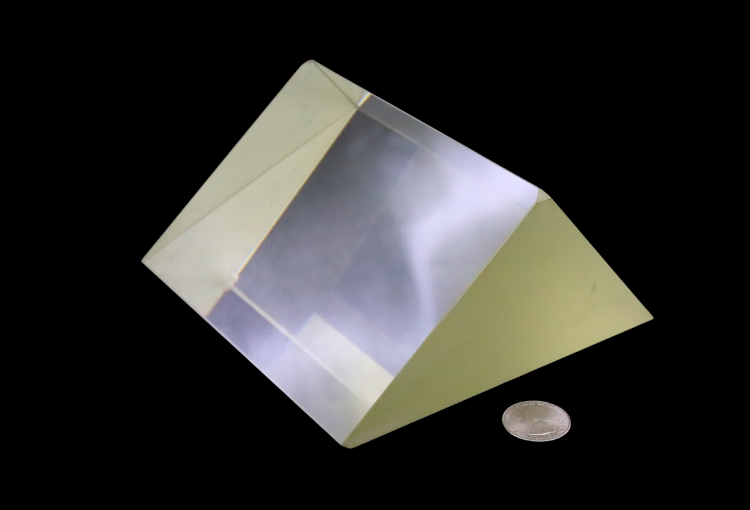

Used for beam deviation, dispersion, and image rotation:

- Available in glass, metal, crystal, or optical-grade plastic

- High-reflectivity coatings (up to 99.9%)

- Precision angles and surface flatness for minimal beam deviation

Avantier’s domes support wide field-of-view applications:

- Transparent to visible, UV, and IR wavelengths

- Minimal beam deflection across varying viewing angles

- Materials: Germanium, BK7, Sapphire, Acrylic, Fused Silica

Applications of Large Optics

Astronomical Telescopes & Space Imaging

- Primary mirrors and secondary mirrors for optical telescope elements (OTE)

- Support wavefront sensing, light collection, and thermal management

- Space-rated coatings and mechanical stability under vacuum and cryogenic conditions

Ultrashort Pulse Laser Compression

- Large-diameter gratings and mirrors for high-peak power pulse compression

- Coatings engineered for high LIDT

- Surface flatness and material homogeneity prevent optical distortion

High-Resolution Optical Imaging

- Increased angular resolution via larger input apertures

- Enables faster acquisition of faint targets with reduced noise

- Critical for earth observation, satellite imaging, and biomedical systems

Optical Metrology

- In-house testing for wavefront error, surface roughness, and coating uniformity

- Interferometry and custom alignment jigs for metrology of non-standard optical components

Beam Expanders and Laser Systems

- Custom-engineered beam expanders for laser delivery and alignment

- Designed for precision alignment in industrial, defense, and scientific applications

- Optimized for high power laser propagation with minimal distortion

Materials for Large Optics

Material | Key Properties | Common Use Cases |

Fused Silica | High thermal stability, UV to IR transparency | Astronomy, laser optics |

BK7 Glass | Cost-effective, excellent visible transmission | Lenses, domes |

Germanium | IR transmission, high refractive index | Infrared imaging, defense optics |

Zinc Selenide (ZnSe) | Broad IR range, low absorption | CO₂ laser systems, thermal imaging |

Sapphire | Scratch-resistant, durable, high melting point | High-end domes, harsh environments |

Chalcogenide Glass | Transparent in MWIR & LWIR | Thermal imaging, remote sensing |

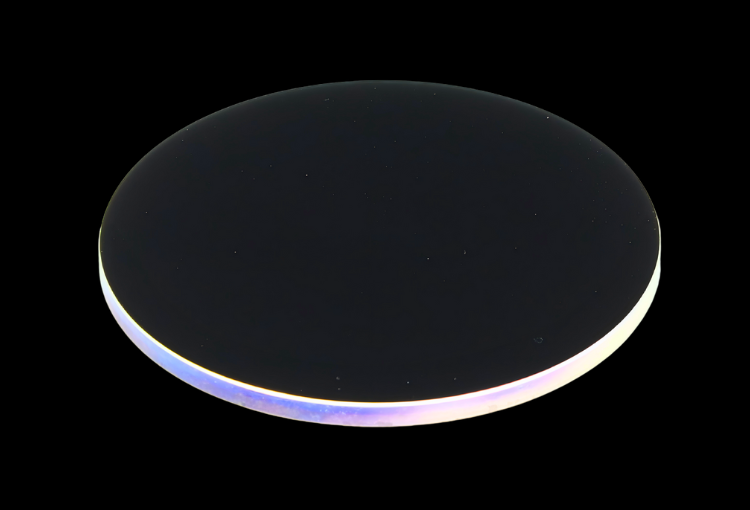

Large Optics Coating Capabilities

High-Performance Coatings for Large-Diameter Optical Components

Avantier provides advanced thin-film optical coatings engineered specifically for large optics—including lenses, mirrors, domes, windows, and prisms up to 1,000 mm in diameter. Our proprietary coating processes ensure superior optical performance for astronomy, aerospace, satellite imaging, defense, laser systems, and semiconductor applications.

With state-of-the-art deposition technology and precision metrology, we deliver high-uniformity coatings for demanding UV, visible, NIR, SWIR, MWIR, and LWIR applications.

Optical Coating Types

Coating Type | Benefits & Applications |

Anti-Reflection (AR) Coatings | Maximize transmission; broadband AR, V-type, and custom wavelength AR coatings |

High-Reflection (HR) Coatings | Dielectric, enhanced metal, and laser-grade coatings with reflectivity >99.5% |

Beam Splitter & Partial Reflective Coatings | Precision R/T ratios (50/50, 70/30, 90/10); interferometry, laser diagnostics, imaging |

Metallic Coatings | Protected and enhanced Aluminum, Silver, Gold for VIS to LWIR |

Specialized & Functional Films | Polarizing, conductive, hydrophobic, abrasion-resistant, and space-grade coatings |

Engineered for Extreme Optical Performance

Our coatings for large optical components deliver:

- Ultra-high transmission/reflectivity across UV–LWIR

- Laser damage-resistant (high LIDT) coatings

- Uniformity <1% across large diameters

- Low scatter and low absorption

- MIL-spec and ISO-certified durability

- Thermal & mechanical stability for space and defense optics

Systems include the Bühler ARES1110, enabling industry-leading coating precision on large substrates.

Coating Capabilities Tailored to Large Optics

- Stress-optimized coating stacks to preserve surface accuracy

- Precision edge control and masking for oversized optics

- Smooth thin-film surfaces for diffraction-limited imaging

- Expertise in coating aspheres, domes, prisms, mirrors, and thick substrates

- Cryogenic & high-vacuum compatible coatings for space environments

From deep-space telescope mirrors to large infrared domes and high-power laser optics, Avantier delivers the coating performance needed for mission-critical imaging and photonics systems.

Upgrade Your Large Optics With Advanced Thin-Film Coatings

Whether you need large-diameter AR coatings, high-reflective coatings, or custom laser coatings, Avantier provides precision engineered solutions with fast turnaround and technical support from concept to production.

At Avantier, we offer expert consultation and rapid prototyping to meet your project’s exact optical needs. Whether you’re sourcing off-the-shelf products or need fully custom engineered systems, our team is ready to assist.

👉 Contact us today to request a quote or discuss your specifications.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.