Large Aperture Optics – Aspherical Mirrors, Lenses & Plane Mirrors

Avantier’s Large Aperture Optics provide ultra-precision performance for astronomy, defense, satellite imaging, laser systems, and advanced research. Our product line includes aspherical mirrors, aspherical lenses, spherical lenses, and plane mirrors, all engineered with large clear apertures (up to Φ2000 mm) to achieve superior imaging quality, aberration correction, and system efficiency. By leveraging advanced manufacturing technologies such as CNC polishing, ion beam figuring (IBF), and magnetorheological finishing (MRF), supported by rigorous interferometric testing and surface metrology, Avantier ensures every optical component meets the highest standards of accuracy, resolution, and reliability.

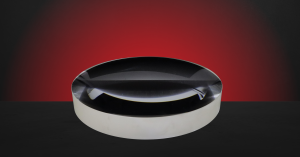

Large Aperture Aspherical Mirrors

Modern optoelectronic instruments are trending toward miniaturization, integration, and lightweight design. Aspherical surfaces play a critical role by:- Increasing design freedom

- Eliminating optical aberrations (spherical, coma, astigmatism)

- Improving imaging quality and resolution

- Reducing the number of optical components

In fields such as national defense, astronomy, basic research, and communication technology, the demand for large aperture optical components is continuously growing due to requirements for higher resolution and imaging precision.

Avantier’s manufacturing capabilities integrate advanced processes including:

- Ultra-precision turning

- CNC polishing

- Ion beam figuring (IBF)

- Magnetorheological finishing (MRF)

These are supported by multi-method inspection such as interferometric testing and surface profile measurement. Our senior engineering team provides seamless software-hardware integration to ensure optical elements consistently meet stringent customer requirements.

Avantier’s Large Aperture Aspherical Mirror Capabilities

Avantier has decades of experience manufacturing large aperture aspherical mirrors with expertise in lightweight materials and high-precision finishing. We offer:- Off-axis parabolic mirrors

- Coaxial parabolic reflectors

- Ellipsoidal (double-curved) mirrors

- High-order aspherical mirrors

- Optical focusing and beam expansion

- Wavefront shaping and optical path control

- High-resolution imaging systems

- Precision alignment in optical engineering

Specifications

Diameter | Φ10 mm – Φ2000 mm |

Clear Aperture | ≥90% |

Surface Accuracy | RMS ≤ 1/200λ (λ = 632.8 nm) |

Surface Quality | 60/40 ~ 20/10 |

Materials | Microcrystal, fused silica, silicon carbide (SiC), monocrystalline silicon, aluminum, Zerodur, H-K9L |

Conic Coefficient (K) | K=-1, -1<k<0, k<-1 |

Surface Roughness | 0.2 nm |

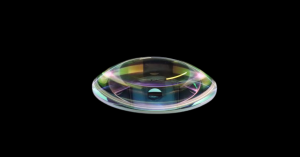

Large Aperture Aspherical Lenses

Aspherical lenses feature non-spherical surfaces that correct aberrations such as spherical aberration, coma, and field curvature, significantly enhancing imaging quality.

Key applications

- Astronomical telescopes – main or secondary mirrors for wide-field and deep-space observation

- High-energy laser systems – beam shaping, focus control, and energy concentration

- Satellite imaging & remote sensing – high-resolution imaging with reduced system weight

- Precision imaging – microscopy, photography, and lightweight lens assemblies

- LiDAR and ranging systems – beam divergence control, higher accuracy in distance measurement

Specifications

Diameter | Φ10 mm – Φ1000 mm |

Clear Aperture | ≥90% |

Surface Accuracy | RMS ≤ 1/200λ (λ = 632.8 nm) |

Surface Quality | 60/40 ~ 20/10 |

Materials | H-K9L, fused silica, Zerodur, etc |

Conic Coefficient (K) | K=-1, -1<k<0, k<-1 |

Surface Roughness | 0.2 nm |

Manufacturing challenges:

The complex curvature of large aspherical lenses requires CNC polishing, ion beam figuring, and ultra-precision metrology. Avantier combines advanced machining with comprehensive testing systems and expert technicians to deliver ultra-precision optical performance.

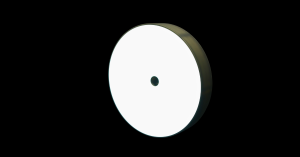

Large Aperture Spherical Lenses

Large-diameter spherical lenses are critical in high-precision optics but present challenges due to their size and required accuracy. The polishing process demands both high surface finish and defect-free quality, making production time-intensive and technically complex.

Applications

- High-precision imaging lenses – for scientific, medical, and industrial research

- Interferometer lenses – for accurate optical measurements and beam focusing

- Semiconductor lithography objectives – nanoscale lithography in semiconductor manufacturing

- Industrial optics – imaging for automation, quality control, and detection

Specifications

Diameter | Φ10 mm – Φ800 mm |

Clear Aperture | ≥90% |

Surface Accuracy | PV ≤ 1/3λ, RMS ≤ 1/200λ (λ = 632.8 nm) |

Surface Quality | 60/40 ~ 10/5 |

Materials | H-K9L, N-BK7, fused silica, Zerodur etc |

Surface Roughness | 0.2 nm |

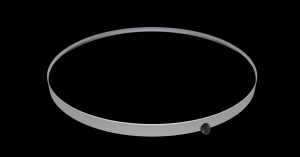

Large Aperture Flat Mirrors

Large-aperture flat mirrors serve as reference surfaces for calibration, beam alignment, and optical path control. Made from high-stability materials such as Zerodur and ULE, they ensure thermal stability, structural integrity, and superior flatness.

Applications

- Optical calibration – system flatness, focus accuracy, and performance verification

- Astronomy & space exploration – telescope calibration under extreme conditions

- High-energy laser systems – wavefront quality and beam direction control

- Research experiments – precision measurement references

Specifications

Diameter | Φ10 mm – Φ2000 mm |

Clear Aperture | ≥90% |

Surface Accuracy | PV ≤ 1/3λ, RMS ≤ 1/200λ (λ = 632.8 nm) |

Surface Quality | 60/40 ~ 10/5 |

Materials | H-K9L, N-BK7, ULE, fused silica, Zerodur |

Surface Roughness | 0.2 nm |

Partner with Avantier for Large Aperture Optics Solutions

Avantier provides end-to-end solutions for the manufacturing of custom large optics, including large aperture aspherical mirrors, aspherical lenses, spherical lenses, and plane mirrors. By combining advanced machining technologies such as CNC polishing, ion beam figuring (IBF), and magnetorheological finishing (MRF) with comprehensive testing methods including interferometry and profilometry, we deliver high-precision, lightweight, and high-performance optical components.

Our optics are trusted in demanding fields such as astronomy, defense, satellites, lasers, LiDAR, imaging, and semiconductor manufacturing.

👉 Contact Avantier today to discuss your custom large aperture optics project and discover how our engineering team can help achieve your performance goals.

We can help you

Share this article to gain insights from your connections!