Precision Copper Mirrors for High-Power Applications

Copper mirrors are essential components in various challenging optical systems, especially those that involve high-power lasers and infrared uses.

At Avantier, we specialize in producing high-performance copper mirrors designed to excel under the most challenging conditions.

Why Choose Copper Mirrors? The Power of Thermal Conductivity

Copper optical mirrors are primarily selected for their exceptional thermal properties and high reflectivity in specific spectral ranges.

- Infrared and Red Light Reflection: Copper is an excellent reflector of infrared (IR) and red light. This makes it an ideal choice for systems operating in these wavelengths.

- Superior Thermal Management: The high thermal conductivity of copper is its standout feature. This allows for the efficient dispersion of excess heat generated by high-power lasers or intense light sources.

This important feature helps copper optical mirrors perform well and stay clear, even in situations that would damage or ruin non-metal mirrors.

- Durability in Extreme Environments: Their robust nature makes them suitable for environments where thermal stability and resilience are paramount.

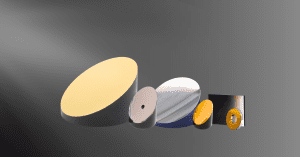

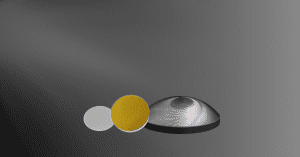

Tailored Performance: Copper Mirror Coatings

While pure copper offers distinct advantages, its optical properties can be further customized and enhanced through various coatings. Avantier produces copper mirrors that may be coated with:

- Protected Gold: Offers excellent reflectivity in the infrared range with added durability.

- Protected Silver: Provides high reflectivity across a broad spectrum, including visible and infrared, while benefiting from copper’s thermal properties.

- Protected Aluminum: Suitable for specific wavelength requirements or when a balance of properties is required.

- Molybdenum: Used for its extreme hardness and durability, often in harsh industrial laser environments.

These coatings allow us to combine the robust cooling properties of the copper substrate with the precise optical performance required for your specific application.

Precision Optics

Unlike ordinary metallic mirrors used in home decorations, precision optical copper mirrors are almost always first surface mirrors. This means the metallic reflective layer (copper or its coating) is deposited on the front surface of the substrate. This design is crucial to:

- Avoid Chromatic Dispersion: Prevents light from separating into its constituent colors as it passes through a substrate.

- Eliminate Ghost Images: Ensures a single, clear reflection without secondary reflections.

The high-quality metallic surfaces of these mirrors require extreme care. For applications demanding greater durability, Avantier can produce protected or enhanced metallic copper mirrors with specialized overcoats.

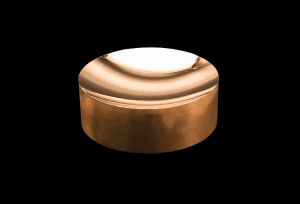

Custom Copper Mirrors at Avantier

At Avantier, we understand that off-the-shelf optics rarely provide the perfect solution. That’s why we specialize in custom copper optical mirrors. We can produce precision copper optical mirrors in any configuration desired, including:

- Plano (flat)

- Spherical

- Aspherical

- Toroidal

We invite you to collaborate with our experienced engineers and optical designers.

Our factories and high-quality measuring tools help us make custom copper and coated copper mirrors. They will meet your needs and follow all industry standards.

Contact us today to place your custom order or schedule your first consultation for high-performance copper mirrors.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.