Aspheric Mirrors

Aspheric mirrors are non-spherical optical mirrors. They play an important part in many high-stakes optical systems, and may be chosen to avoid the spherical aberration that is omnipresent when spherical optics are used. In many situations, a single aspheric mirror can take the place of a complex multi-part design based on spherical elements.

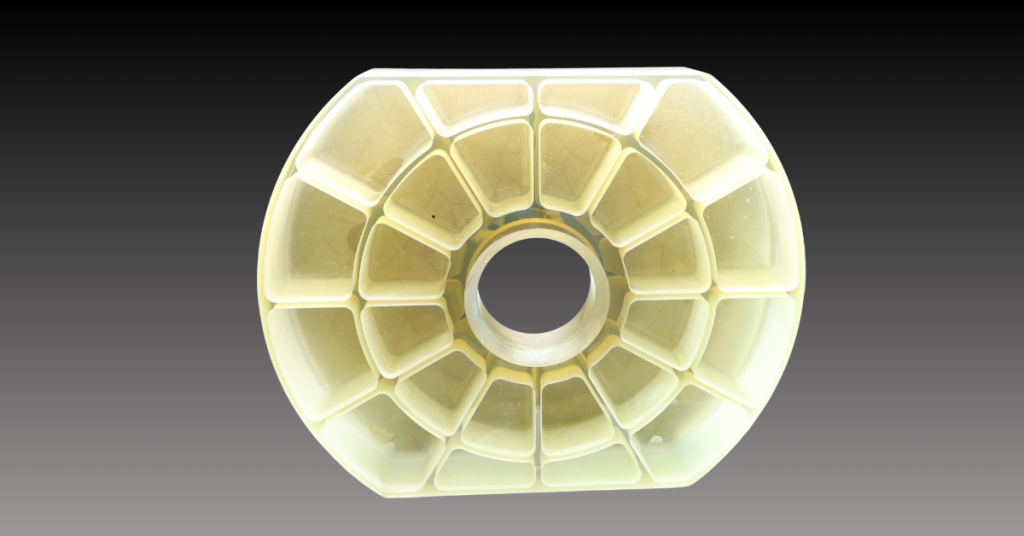

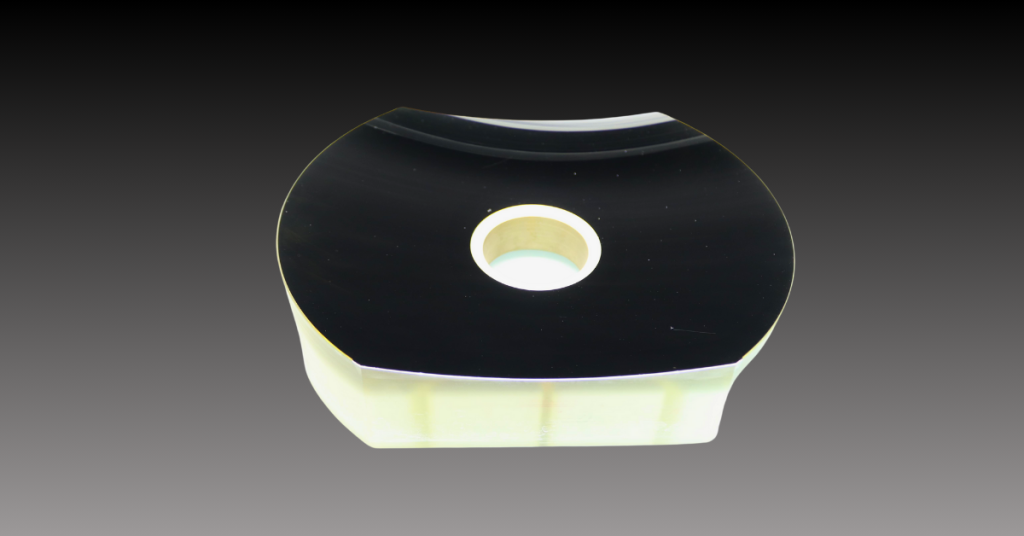

An aspheric mirror will be rotationally symmetrical, but the radius of curvature will vary radially from the center to the edge of the lens. Aspheric surfaces may be specified using orthogonal coefficients (Qbfs and Qcon) or through a surface profile (sag). While some aspheric mirrors deviate so slightly from a spherical model that the human eye cannot discern the difference, others have a very obviously non spherical profile. The mirror you need will depend on your specific application and imaging needs.

Benefits

Aspheric mirrors are more expensive to produce than standard spherical optics, but the performance advantage often makes the extra cost well worth it. Benefits include:

- Sharper focusing

- Larger aperture size

- Better ability to focus and collect light

- Reduced or eliminated spherical aberration, marginal astigmatism, and distortion

- Fewer elements/ lighter weight in optical assemblies

Specifications:

- Materials: Zerodur

- Width: 176mm±0.1mm

- Thickness: 5mm±0.1mm

- Coating: protected silver R>95%@430-5000nm

Applications

Aspheric mirrors have many applications but are especially desirable where weight and size must be kept at a minimum- for example, in space borne optical systems. Highly aspheric mirrors are also often incorporated in astronomical telescopes, integrated with a segmented spherical primary mirror to reduce spherical aberration. In modern high power laser systems, they are used to achieve extremely high power densities through pinpoint focusing.

Production

Aspheric mirrors cannot be produced using the same bulk production methods used for spherical mirrors, hence the higher cost. Aspheres are sometimes produced using precision molding techniques. These mirrors are shaped and polished one by one using diamond turning and computer-numerical-control (CNC) equipment, by an optical tech who mans the CNC and programs it to shape the optic as desired. Magneto-rheological finishing (MRF) can be used when an mirror with particularly fine surface quality is required.

Factory Standard

Diameter | Aspherical offset | Roughness | Surface Precision(PV) | |

Aspheric Mirror (Off-axis Parabolic Mirror ) | 50mm-1200mm | 0-20um | <1nm | 0.06um |

20-2000um | <2nm | 0.1um |

Custom Aspheric Mirrors at Avantier

At Avantier we focus on creating custom optics that are designed and manufactured per our clients’ specifications. Rather than offer you in-stock mirrors that might approximately do what you want, we’d like to work with you to create the ideal optic for your application. Bringing in more than five decades of design experience, our optical engineers and designers can help you come up with a design that fully meets your needs and expectations.

Designing is just the first step. Once you’ve decided exactly what you want, we are able to create custom aspheric mirrors designed just for your application. Our extensive supply network and state of the art in-house manufacturing capabilities enable us to source any substrate you might require and produce the high precision optics that you need. When you work with Avantier you know you will receive carefully tested, high quality optics that meet and exceed all applicable standards. Please contact Avantier today to schedule an introductory consult or order a custom optic.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.