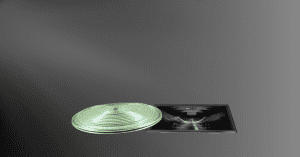

Pancake Lenses

Avantier’s Pancake Lens is an advanced optical solution designed for next-generation Virtual Reality (VR) headsets. Featuring a folded optical path structure, the Pancake lenses enable thinner, lighter, and more immersive head-mounted displays by integrating reflective polarizing films and quarter-wave plates.

This lens is engineered to meet the demanding requirements of modern VR optics, delivering enhanced image clarity, optimized space usage, and unparalleled miniaturization.

Key Features

- Folded Optical Path Design

Utilizes multiple internal reflections to achieve a compact structure while maintaining excellent image quality. - Miniaturization

- Reduces optical thickness by 60–70%

- Cuts headset weight by 30–40%

- Shortens the distance between the display and the lens

- Enhanced Image Performance

- Multi-lens combination corrects distortion and chromatic aberration

- Clearer edge details and improved contrast

- Efficient Space Utilization

Frees up interior space for sensors, batteries, and additional modules in VR devices.

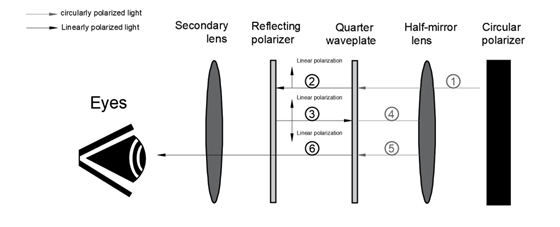

The working principle of Pancake structure

The Pancake structure combines a reflective polarizing film, quarter-wave plate, and semi-reflective mirror to fold the optical path efficiently. Light transmission involves:- Conversion between circularly and linearly polarized light

- Strategic internal reflections

- Effective stray light suppression

- Optimized light transmittance to the user’s eye

Applications

- Virtual Reality Headsets

- Folded Optical Systems in Augmented Reality (AR) Windshields

- Curved Head-Up Displays (HUDs)

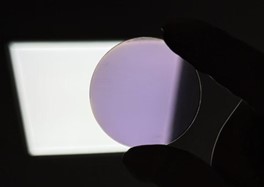

Manufacturing Capability: Polarizing Film Lamination

The lamination process plays a vital role in Pancake lens performance. It involves adhering a polarizing film and quarter-wave plate onto curved lens surfaces with extreme precision.Technical Highlights:

- Optical axis tolerance: ±0.5°

- Surface shape accuracy: PV < 2 fringes @ 633 nm

- Visual inspection pass rate: ≥99.5%

Process Innovations:

- High-precision vacuum laminating (±1 µm)

- Low-modulus optical adhesives (≤3 MPa)

- Advanced visual alignment systems

Case Study

Lens Type: Convex-concave H-K9L

Diameter: Φ42 mm | Radius: 130 mm

Lamination: Polarizing film on convex surface

Results:

- 100% cosmetic quality

- Surface deviation: PV = 1.8 fringes

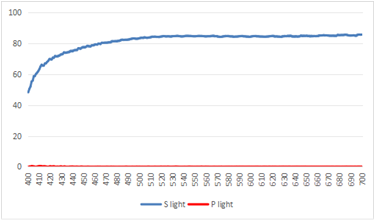

- Transmittance deviation: <1% (400–700 nm)

- Polarization degree: >99.5%

- Optical axis deviation: 0.3°

Future Outlook for Pancake Lenses

As VR devices trend toward thinner profiles (<30 mm) and wider fields of view (>150°), our Pancake Lens technology is advancing to meet new challenges:

- Nanoscale precision bonding for freeform surfaces

- Machine vision with AI for automated defect detection

- Innovative materials: flexible polarizers and stretchable adhesives

Partner with Avantier to unlock the full potential of lightweight VR with our industry-leading Pancake Lenses technology and precision lamination capabilities. We are committed to supporting high-volume production with exceptional optical quality, helping bring VR from premium experiences to everyday accessibility.

Ready to integrate next-gen optics into your VR system?

Contact us today to learn more about our customizable Pancake Lens solutions.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.